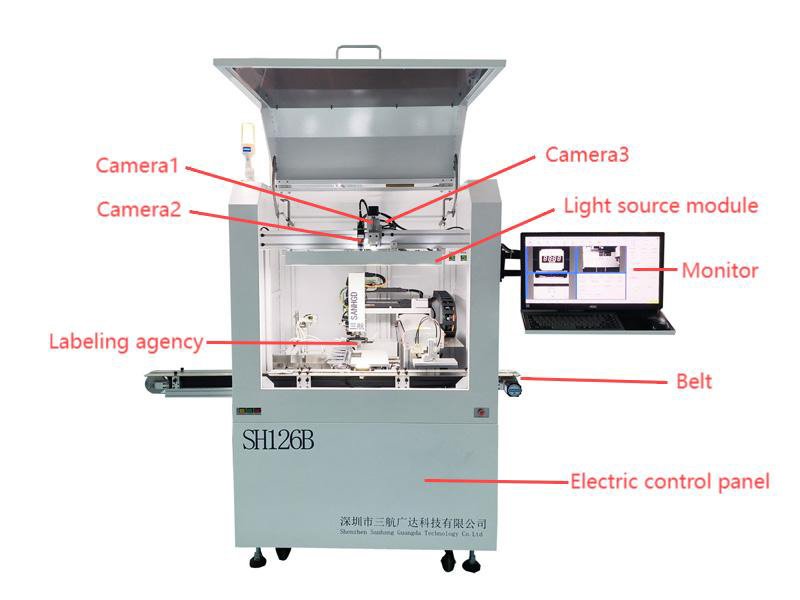

This equipment is designed for the laminating needs of film sheets that are sheet-like incoming materials, and the laminating speed will be faster compared to the independent feeding flyer. It adopts three-camera positioning technology, membrane and shell material are visualized separately, and the laminating can reach higher precision.

Feed direction

Membrane specifications and related requirements:

1、Feeding direction membrane spacing requirements for equidistant

2, each piece of membrane feeding direction A size error is less than 2mm

3, the thickness of the base paper is greater than 0 . 1rrm, it is recommended to prioritize the use of plastic substrate paper

4, the base paper frame requires four sides cut neatly (regular rectangle, no obvious trapezoid, parallelogram)

Application areas: digital tubes, electrical control panels, product windows, remote control, die-cutting composite and so on.